Slagless technology development had as its objective to avoid the accumulation of slag along the water-cooled oxygen-blowing lances body in the Basic Oxygen Furnace (BOF).

A uniquely special design, combined with modern engineering, grants Slagless a superior performance compared with other current technologies.

Its specific capacity to extract heat over the length of the lance lower body provides greater structural stability, longevity, less requirement for nozzle replacement due to erosion wear and higher operational stability.

During the steel making process, Slagless allows greater flexible of operational parameters, enabling significant gains in the process, including: flexibility in adjusting the lance height relative to the bath, reduction of blowing time, increase of metallic yield, reduction in oxygen consumption and more.

Considering maintenance and ergonomic aspects, Slagless technology reduces the necessity of human intervention to clean the lance, minimizing personnel presence in hostile environments and high risks regarding safety.

• Lance tip replaced by cartridge;

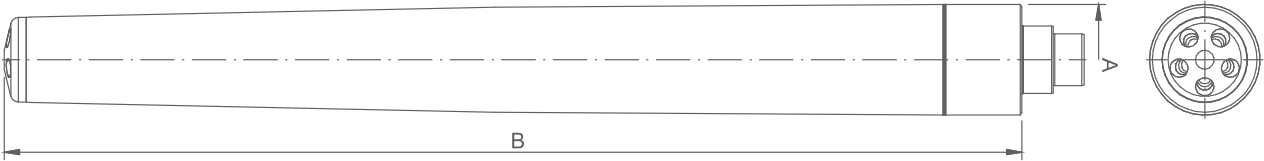

• Cartridge made of copper with specific dimensions to each

converter;

• System with high capacity of heat exchange due to the

special design developed by Lumar and ongoing support in

the process development.

• High performance nozzle;

• Significant reduction of lance skulls;

• Increased metallic yield/income.

• Reduction of FeO in slag;

• Reduction of soluble oxygen in steel;

• Reduction of flow and increased lifetime of tuyeres;

• Reduction of blow time.

• Reduction of human exposition for the cleaning of the lance

with torch / oxy cut;

• Reduction of human intervention in high-risk conditions of

temperature, dust, hot particles and high levels of carbon

monoxide;

• Reduce labor to change lances;

• Reduce labor to clean lances.

back

back