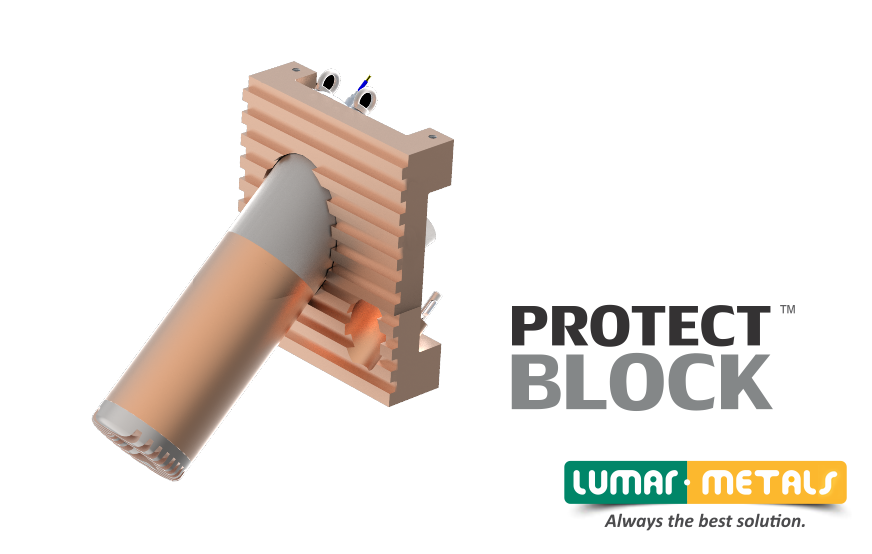

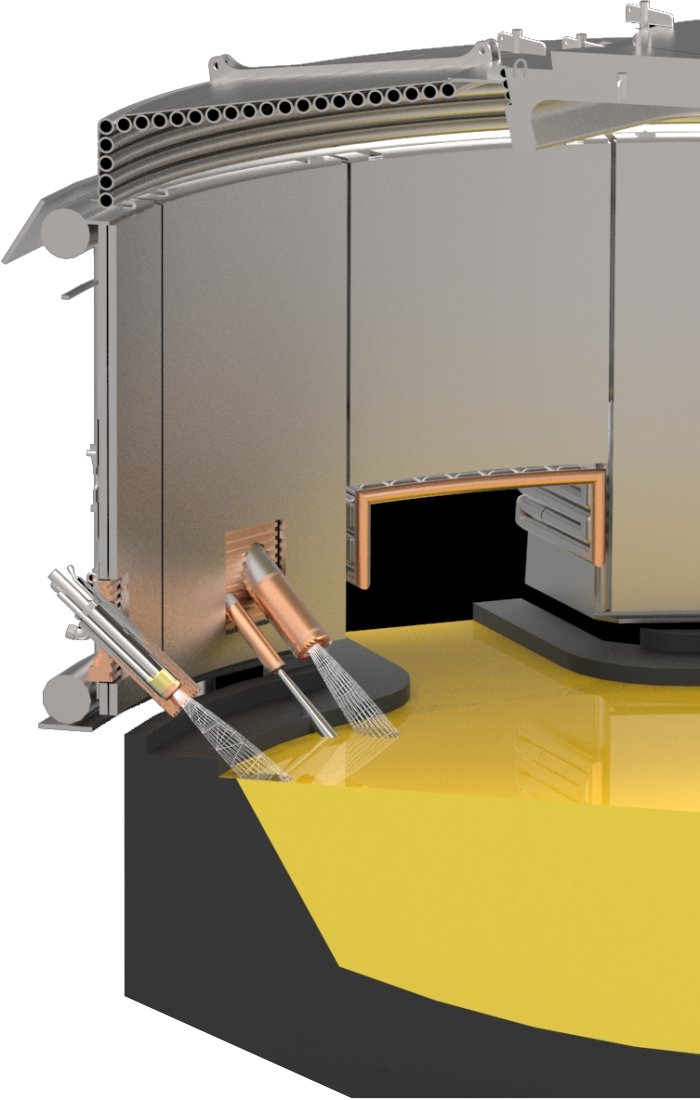

The Protect Block is a pure copper block with the purpose of promoting a reduction of the distance between burner/injector and liquid bath in an electric arc furnace, for an effective increase in the oxygen penetration into the liquid bath aimed at reducing the refining time and oxygen consumption. It was designed to allows the assembly the FlexOx injector and the powder carbon injector at the same block.

For the Protect Block to resist the extreme exposure to which it is subjected, such as high temperatures, flame rebounds and scrap impacts during the early melt-in of the furnace charge, it was necessary to combine modern engineering in heat transfer and material quality, as well as special coatings to resist all the effects of the furnace environment.

The engineering applied to the Protect Block provides it with considerable service lifetime potential, less maintenance, less.

• Weight reduction up to 50% when compared with the

conventional sidewall burner/injector blocks;

• Lower area of exposure within the furnace;

• High impact resistance: up to 3,000 kg (6,614 lbs) of direct

impact;

• Composed of light-weight independent modules: Support

Frame, Frame and Protect Block.

• Equipped with thermocouple to prevent back flame

damages;

• Allows carbon injector assembly together with oxygen

• Increased operational safety;

• High resistance of material impact;

• Effective protection for the burner/injector;

• Easy exchange of the burner/injector;

• Low cost compared with others blocks.

back

back