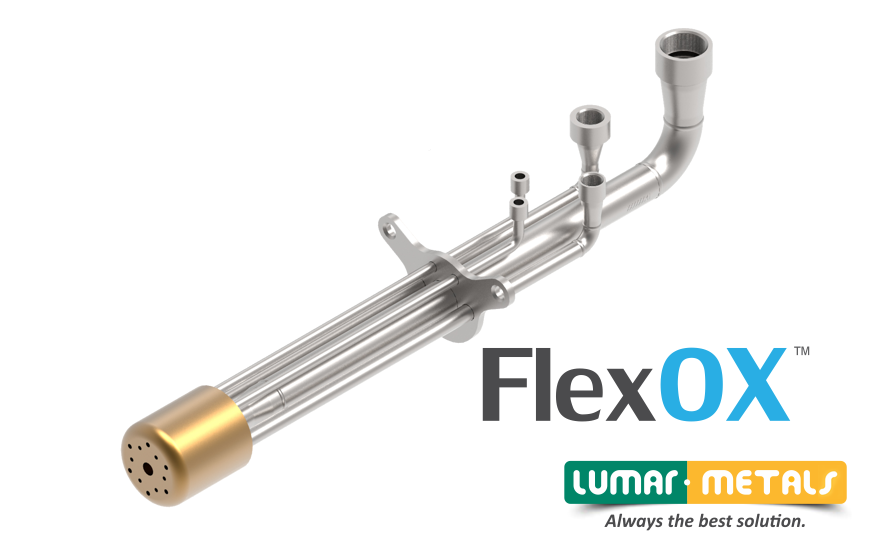

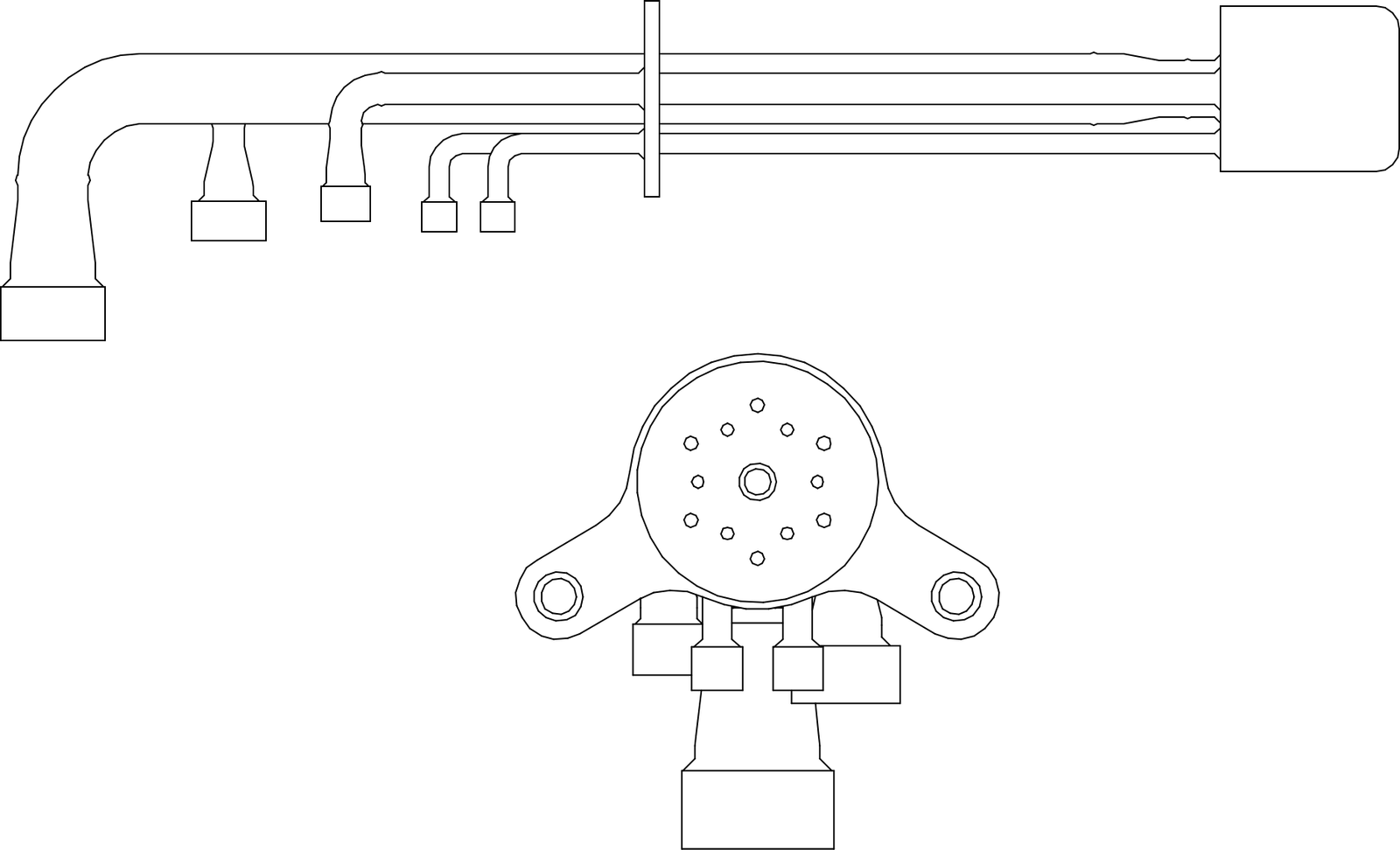

FlexOx is a technology aimed to increase the productivity in Electric Arc Furnaces (EAF) through the more efficient injection of the oxygen and fuel gas. Designed to flows up to 3.000 Nm3/h, the nozzle of the injectors are customized for each customer, allowing the optimization of the process and de extended life time of the equipment.

FlexOx has a special cooling system that requires low water volumes for operation, making the equipment lighter and more ergonomic, while reducing installation and maintenance costs.

• Flow of Main oxygen up to 3.000 Nm3/h (1,902 SCFM);

• Burner power up to 5.0 MW;

• Requires less cooling water when compared to conventional injectors, even though it is mounted closer to the liquid bath;

• Less weight when compared with conventional injectors (in average: 25 kg / 55 lbs);

• Easy maintenance with low ergonomic effort;

• Deep penetration and greater stirring;

• Reduction of oxygen consumption;

• Reduction of electrode and refractory consumption;

• Reduction of electrical energy consumption;

• Increased productivity;

• Low equipment cost;

• Low maintenance cost.

back

back