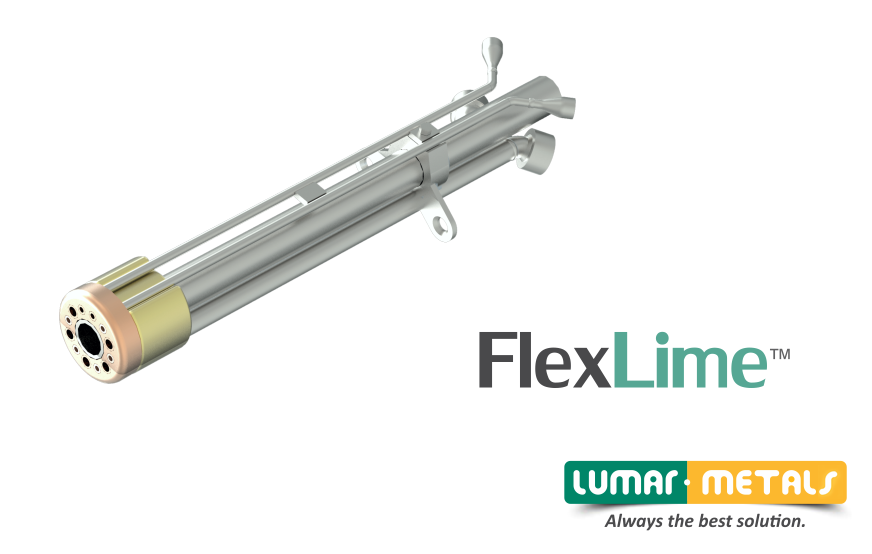

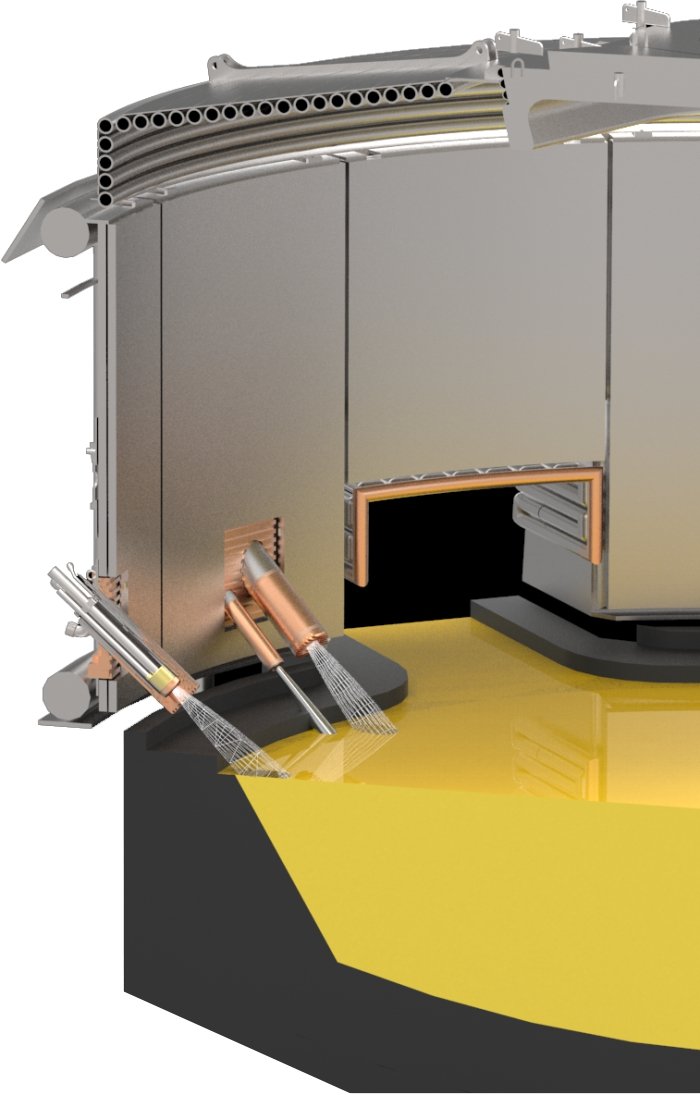

FlexLime is an equipment that promote the efficient particulate lime injection into the Electric Arc Furnace (EAF), aimed the homogenization of the bath, increasing the slag neutralization to protect the refractory lining and maximizing the extraction of undesirable elements in the metal molten.

The FlexLime is equipped with a burner mode to assist the fusion of the scrap disposed in front of the equipment and allow the early lime injection.

The FlexLime is assembled at the furnace through the Protect Block, that promote the proximity to the bath for more efficiency.

• Particulate lime injection rate up to 80 kg/ min (176 lbs/min);

• Burner power up to 5.0 MW;

• Requires less cooling water when compared to conventional injectors, even though it is mounted closer to the liquid bath;

• Less weight when compared with conventional injectors ;

• Easy maintenance with low ergonomic effort.

• Reduction of lime consumption;

• Reduction of the phosphorus content of the bath is facilitated;

• Ability to promote quick formation of slag;

• Reduction of electrode and refractory consumption;

• Allows dynamic control of slag formation.

back

back