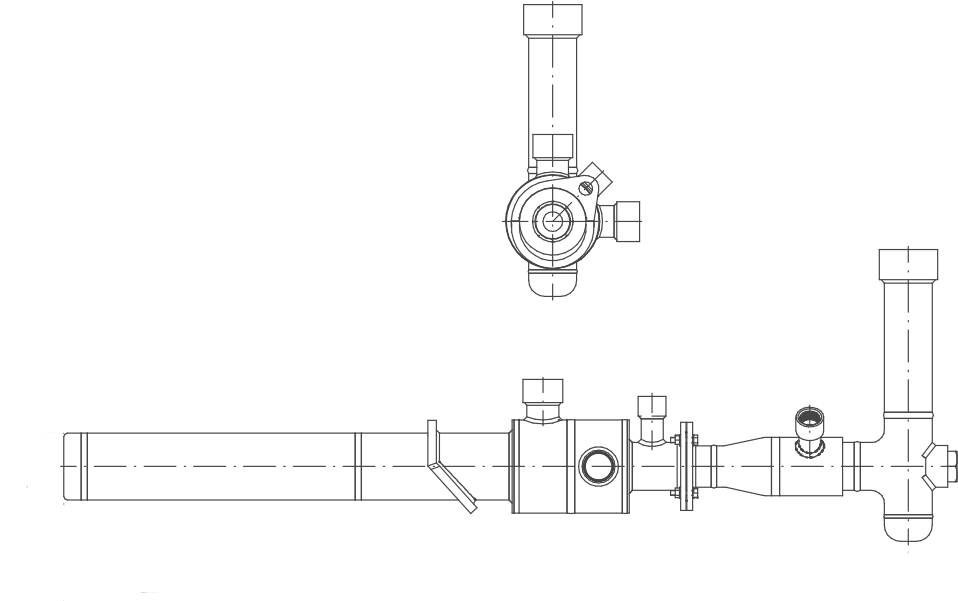

Power Carbon is designed to promote an efficient carbon injection into the Electric Arc furnace (EAF) thanks to your special system of powder acceleration.

The Power Carbon injector allows to module the speed of the powder carbon injected to serve different purposes during the process of melting and refining.

At low speeds, it is perfect to foam the slag and reduce the iron oxide content, increasing the metallic yield. At high speeds, allows adjustment of the carbon in the molten metal.

The Power Carbon has a easily replaceable consumable “wear-tube” which protects the equipment from the abrasion of powder carbon, thereby preventing premature water leak and promoting the extending life time of the equipment.

• Powder carbon injection rate from 5 to 60 kg / min (11 to 222lb / min);

• Requires additional compressed air supply to operate at high speed powder carbon injection (máximun pressure required: 4 bar);

• Available for assembly on all models of Protect Block, together with the oxygen injector.

• Reduction of powder carbon consumption;

• Ability to promote quick formation of foamy slag;

• Reduction of electrode and refractory consumption;

• Low maintenance cost;

• Easy maintenance with low ergonomic effort.

back

back