Lumar Metals, founded in 2000, provides technological solutions for the metallurgical industry, reducing costs and improving product quality.

Phone: +1 (440) 444 0430

36901 American Way, Suite 7

Avon, Ohio 44011

Phone: + 55 31 3828 1000

Rod. MG 232 - Km 09, 70

Santana do Paraíso/MG,

Brasil,

CEP: 35.179-000

Rua Maraquê, 190, Iguaçu

Ipatinga/MG,

Brasil, CEP: 35.162-091

Av. Urias Carlos de Sousa, 750, Silvana

Caratinga/MG, Brasil, Cep: 35.317-000

Mobile: +91 9980111933 Regus Solitaire Business Centre Pvt Ltd, 4th Floor, Gumidelli Commercial Complex, 1-10-39 to 44, Old Airport Road, Begumpet, Hyderabad – 500016. Telangana. INDIA. .

Monday to Friday: 7:30am to 5:30pm Saturday and Sunday: Closed

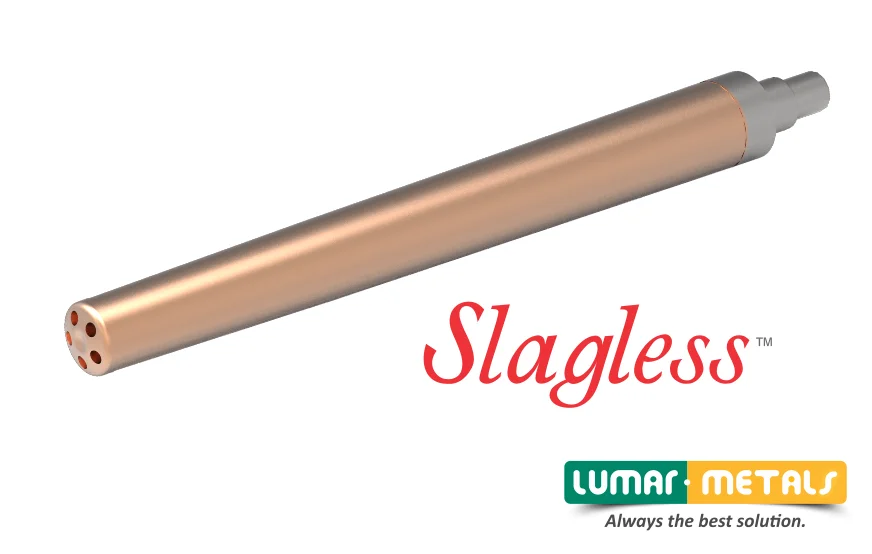

SLAGLESS – Advanced Oxygen Lance Technology for BOF Converters

The SLAGLESS is an innovative technology developed to prevent slag accumulation along the body of oxygen-blowing lances in Basic Oxygen Furnace (BOF) converters. Its high-efficiency heat extraction system along the lower body of the lance ensures greater structural stability, extended lance lifespan, and reduced nozzle wear and replacement frequency.

The SLAGLESS technology is a major breakthrough in oxygen-blowing processes, delivering higher efficiency, improved safety, and cost savings in steel refining for BOF converters.

SLAGLESS CLEAN UP – Post-Combustion Technology for BOF Converter Mouth Cleaning

The SLAGLESS CLEAN UP is an evolution of the SLAGLESS technology, incorporating a post-combustion module for the efficient cleaning of the BOF (Basic Oxygen Furnace) converter mouth. During oxygen blowing, this system directs specialized jets to remove slag and metallic droplet residues, significantly reducing the need for manual cleaning.

The SLAGLESS CLEAN UP is the ideal solution for steel plants looking to automate converter mouth cleaning, ensuring higher efficiency, safety, and operational stability.

SLAGLESS MULTI – Post-Combustion Technology for Increased Metallic Yield and Shorter Blowing Time

The SLAGLESS MULTI is an advancement of SLAGLESS technology, designed to optimize the oxygen-blowing process in Basic Oxygen Furnace (BOF) converters. It incorporates secondary post-combustion nozzles, which increase the reaction rate in the first minutes of the blow, allowing for a higher scrap load and reduced blowing time, while maintaining refining efficiency.

The SLAGLESS MULTI is the ideal solution for steel plants aiming to enhance productivity, reduce costs, and optimize BOF conversion processes.

Slagless Unlimited

Modularity, flexibility, and safety in a single system.

Slagless Unlimited represents the evolution of Lumar Metals’ traditional Slagless Technology. With an innovative concept, the solution integrates multiple advances into a modular system, allowing for greater customization flexibility, lower trial costs, and a significant reduction in operating costs.

The system architecture consists of:

Tip

Optimized blowing nozzles with various configurations (including angular and perpendicular angles, central nozzle, asymmetrical models, and PC models) that ensure jet precision and thermal efficiency.

Module 1

Special Lumar tube, with or without intermediate PC. Provides structural robustness and thermal stability to the assembly.

Module 2

Variety of configurations with steel, copper, and PC Clean Up Technology options. Simple and easy assembly like a conventional lance, with a focus on durability and continuous performance.

Slagless Sublance

More precision. More stability. More safety.

The Slagless Sublance is an innovation developed by Lumar Metals to increase the reliability and performance of the blowing process in the BOF.

The Slagless Sublance is another Lumar solution that combines applied engineering and operational safety, with ongoing technical support, to ensure the best performance in your BOF.

Lumar, attentive to customer needs, developed and improved the sub-lance concept.

Launches the exclusive SLAGLESS SUB-LANCE. This new technology concept maximize measurement efficiency and effectiveness to achieve the following benefits:

However, if traditional sub-lances are still required, Lumar is ready to supply them as per design specified by the customer.

We also offer our dedicated team for replacement, repair, and maintenance services for sub-lances and blowing lances, as well as a favorable rental agreement and conditions geared towards the continuous pursuit of superior performance, applied to products bearing the Lumar Metals product engineering brand.

SUB-LANCE LUMAR CONVENTIONAL – Technology for Precise Measurement and Control in BOF Processes

The SUB-LANCE LUMAR CONVENTIONAL is an advanced technology designed to optimize measurement and control in Basic Oxygen Furnace (BOF) processes. Its innovative design ensures greater accuracy in temperature and carbon content readings, allowing real-time adjustments for more efficient steel refining. Additionally, it significantly reduces the need for manual intervention, enhancing operational safety and productivity.

The SUB-LANCE LUMAR CONVENTIONAL is the ideal solution for steel plants looking to enhance efficiency, improve process accuracy, and increase safety in BOF operations.

OPTY TIP – Advanced Technology for Optimizing Lance Tip Lifespan

The OPTY TIP is an innovative solution designed to extend the lifespan of oxygen-blowing lance tips in Basic Oxygen Furnace (BOF) converters. With an optimized design and detailed performance analysis, this technology enhances oxygen jet stability, reduces operational costs, and provides greater metallurgical control in the steel refining process.

The OPTY TIP is the ideal choice for steel plants aiming to reduce costs, improve BOF process efficiency, and extend the lifespan of oxygen-blowing lances.