Lumar Metals, founded in 2000, provides technological solutions for the metallurgical industry, reducing costs and improving product quality.

Phone: +1 (440) 444 0430

36901 American Way, Suite 7

Avon, Ohio 44011

Phone: + 55 31 3828 1000

Rod. MG 232 - Km 09, 70

Santana do Paraíso/MG,

Brasil,

CEP: 35.179-000

Rua Maraquê, 190, Iguaçu

Ipatinga/MG,

Brasil, CEP: 35.162-091

Av. Urias Carlos de Sousa, 750, Silvana

Caratinga/MG, Brasil, Cep: 35.317-000

Mobile: +91 9980111933 Regus Solitaire Business Centre Pvt Ltd, 4th Floor, Gumidelli Commercial Complex, 1-10-39 to 44, Old Airport Road, Begumpet, Hyderabad – 500016. Telangana. INDIA. .

Monday to Friday: 7:30am to 5:30pm Saturday and Sunday: Closed

FLEXOX – Supersonic Oxygen Injector

FLEXOX is a supersonic oxygen injector designed for Electric Arc Furnaces (EAF), offering high efficiency and operational cost reduction. Its exclusive design and advanced technology ensure increased productivity and resource savings while supporting sustainable practices in the steelmaking industry.

Technical Features:

Benefits:

FLEXOX is the ideal solution for companies seeking innovation, efficiency, and sustainability in the steel industry.

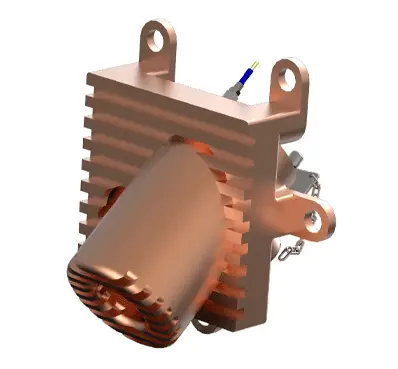

FLEXOX EBT – Supersonic Oxygen Injector for the EBT Region

The FLEXOX EBT is a supersonic oxygen injector specifically designed for installation in the EBT (Eccentric Bottom Tapping) region of Electric Arc Furnaces (EAF). Its advanced engineering ensures better thermal efficiency, greater control over the melting process, and a significant reduction in consumable costs.

Technical Features:

Benefits:

The FLEXOX EBT is the ideal solution for optimizing EAF performance, delivering greater operational efficiency and cost savings in steelmaking.

FLEXOX SHORT – Compact Supersonic Oxygen Injector

The FLEXOX SHORT is a compact supersonic oxygen injector, designed for smaller Electric Arc Furnaces (EAF) or applications with space restrictions. Its advanced technology ensures high oxygen injection efficiency, better process control, and increased productivity.

Technical Features:

Benefits:

The FLEXOX SHORT is the perfect solution for operations requiring efficient, compact, and easy-to-install equipment.

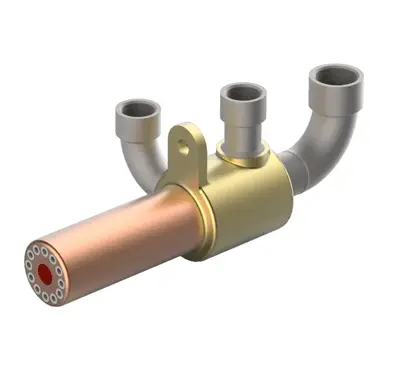

PROTECT BLOCK EBT – Copper Block for Protection and Injection in the EBT Region

The PROTECT BLOCK EBT is a high-durability copper block designed to support and protect the FlexOx EBT and Power Carbon injectors in the EBT (Eccentric Bottom Tapping) region of Electric Arc Furnaces (EAF). Its optimized design enhances thermal efficiency, extends the lifespan of injectors, and ensures greater operational safety.

Technical Features:

Benefits:

The PROTECT BLOCK EBT is a robust and efficient solution for those seeking enhanced protection, safety, and performance in the EBT region of the furnace.

POWER CARBON – Carbon Injector for Foamy Slag Formation

The POWER CARBON is a high-efficiency carbon injector designed for precise coke injection in Electric Arc Furnaces (EAF). It directly contributes to foamy slag formation, enhancing energy efficiency, reducing thermal losses, and lowering consumable usage in the steelmaking process.

The POWER CARBON is the ideal choice for steel plants seeking efficiency, cost savings, and sustainability in EAF melting processes.

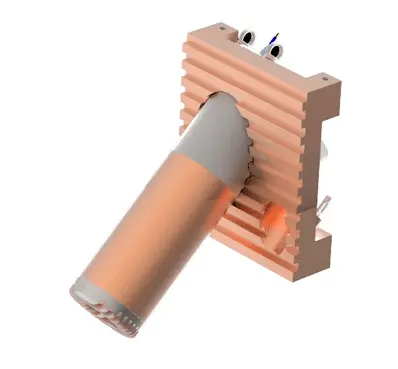

EASY BLOCK – Compact Copper Block for Injectors

The EASY BLOCK is a compact and optimized copper block designed to support the installation of FlexOx Short and Carbon Lance injectors in Electric Arc Furnaces (EAF). Its innovative design enhances operational safety, improves cooling efficiency, and simplifies maintenance, making it ideal for smaller furnaces or installations with space constraints.

The EASY BLOCK is the perfect solution for operations requiring a compact, efficient, and secure support for injectors in Electric Arc Furnaces.