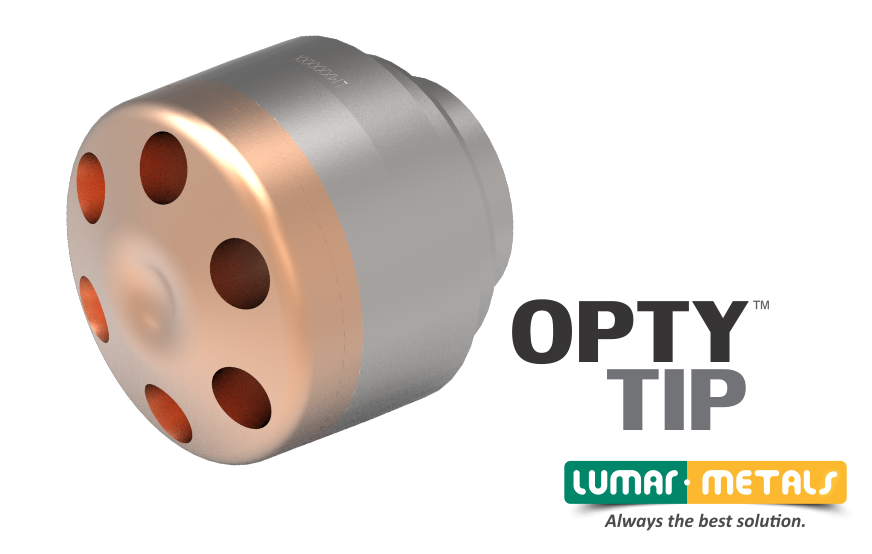

Opty Tip is customized for the specific needs of each client in order to ensure the stability of supersonic jet during oxygen injection through nozzles into BOF vessel.

The design and dimensions of supersonic nozzles have direct impacts on the operational stability of blow in a converter, with gains in oxygen consumption, oxidation reduction and process time.

The Opty Tip has two oxygen output sets that determine two blowing conditions:

The first group consists on the main convergent divergent nozzles responsible for refining the bath.

The internal geometry of the supersonic nozzles in this first group has unique characteristics arising from the desired flow and available pressure of each customer.

Every nozzle for each client receives an ID after Opty Tip design.

The second group consists of secondary jets with varied functions at each stage of the blowing process.

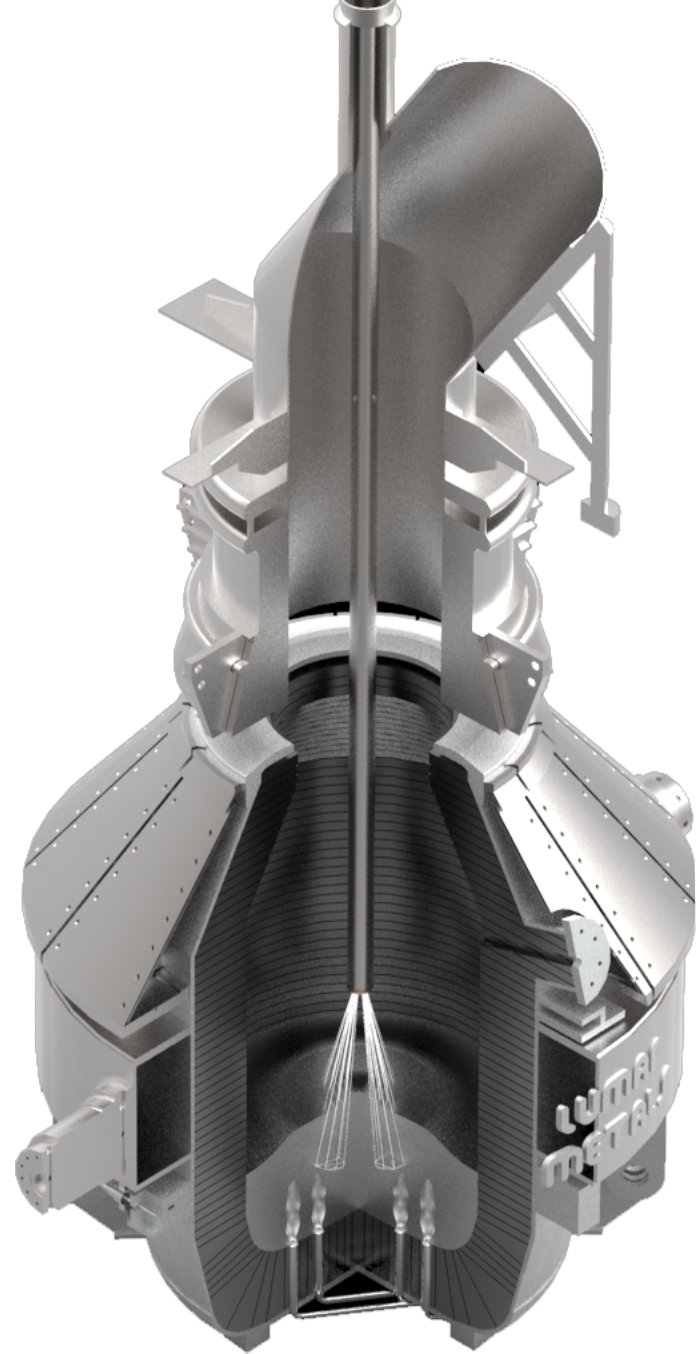

The first function of the process, post combustion takes place (reaction of oxygen with carbon monoxide generated by the main jets).

The second function is to help to accelerate the reactions with carbon by increasing the oxygen jet velocity.

The last function is to increase oxidation in order to retain formed slag elements.

• Pressures between 6 to17 kgf/cm2 (85 to 241 lbs/inch2);

• Flows between 6.000 to 60.000 Nm3/h (3,800 to 38,000

scfm);

• Angles of.

• Lower cost;

• Increase process stability;

• Increase nozzle lifetime;

• Ongoing support in the process development;

• Reduce consumption of electrode and refractory.

back

back